How Are UV Optical Components Used for Sterilisation?

17th Jun 2020At a time when sterilisation, hygiene and disinfection has never been more critical, Knight Optical – the leading supplier of on-spec, metrology-tested, premium-quality optical components – explores how the ultraviolet (UV) end of the spectrum is helping with sterilisation and uncovers some of the optical components that aid UV devices.

When COVID-19 struck the globe in earnest this year, and the world discovered an insatiable appetite for stockpiling hand sanitisers, several substitute methods of sanitation were actively explored. From home-made essential oil-based gels to hydrogen peroxide and white vinegar alternatives, sanitation secrets are still being shared worldwide in a bid to reduce the spread of infection. Meanwhile, manufacturers devotedly pivoted their production lines to assist with much-needed PPE production and disinfection products. In the UK alone, corporations came together to help the NHS. For example, architect firms used 3D printers to fabricate face visors; aerospace businesses operated 24/7 to build life-saving ventilator parts, and luxury carmakers put their machines to work for hospital gown production1. Another article that made its way to hygiene wish lists were UV sterilisation devices; however, many people were – and still are – unaware of the danger that home usage of UV lights can cause. As a result, the World Health Organisation (WHO) issued a warning to the public not to use UV lamps to disinfect their hands and other areas of their skin2. Below we explain why personal use of UV lamps (particularly UVC types) pose a hazardous risk to the public.

Sterilisation Vs Disinfection

Before we continue, it is essential to note the difference between sterilisation and disinfection. Essentially, they both decontaminate; however, sterilisation removes all organisms while disinfection removes most pathogenic organisms. Thanks to its destruction of microscopic life, UV sterilisation is invaluable in healthcare settings and is frequently used in hospitals to reduce the risk of hospital-acquired infections (HAIs). In fact, throughout the pandemic, more NHS Trusts have turned to UV; with some hospitals using devices in a bid to try and re-use elusive PPE3. Meanwhile, innovators around the globe are experimenting to kill the notorious virus with UV light. One such company is UVD Robots whose UV Disinfection Robot – a self-driving device that uses light beams to kills microbes with UV light4 – is just one of the innovations that is proving popular in medical settings.

Learn Your ABCs

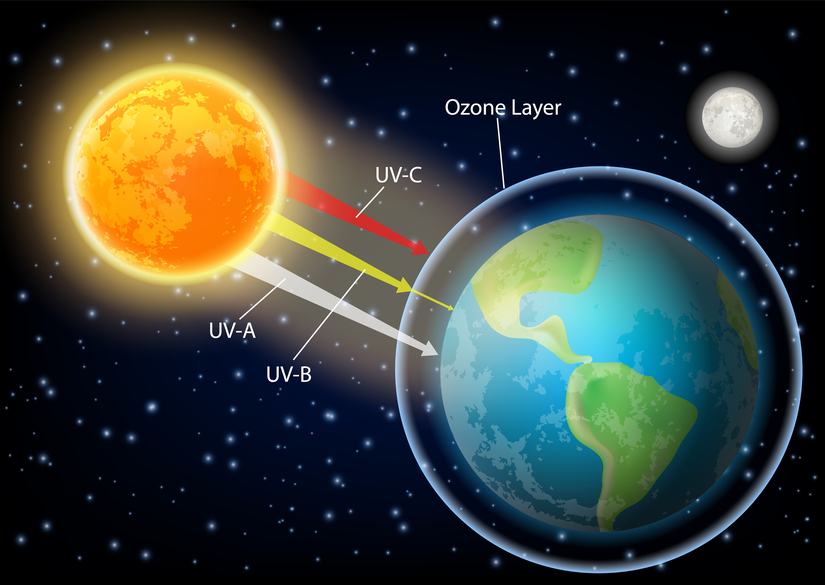

With all these COVID-19-busting UV-powered innovations emerging in the sterilisation marketplace, it is worth noting; however, that a UV device manufactured to tackle COVID-19 contamination is far from simple. The UV spectrum is somewhat multifaceted, and its radiation is split into three types of rays. Firstly, there’s UVA, which is also known as ‘long-wave light’. This type of light accounts for 95% of the radiation that reaches the earth’s surface. Covering the 315 to 400nm range, UVA penetrates deep into the skin, causes ageing and is linked strongly to skin cancer. Meanwhile, UVB – which covers the 280 to 315nm range – is known for its sun burning capabilities, working through the superficial layers of skin, and is a well-known culprit for skin cancer.

While both A and B varieties are incredibly hazardous to our skin, the third and final ray, UVC (which covers the 100–280nm range), is by far the most perilous – and, unfortunately, is the type of UV radiation that would be required to challenge COVID-19. In summary, the shorter the wavelength of UV, the more danger it poses to our health, and as UVC has a short wavelength, it raises the most risk. That said, luckily for us, UVC is absorbed by the earth’s ozone.

Thanks to its ability to deactivate the DNA of bacteria and impair their ability to multiply5, artificial UVC light devices have been hitting the headlines lately with their coronavirus spread-reducing potential. Since the outbreak of COVID-19, engineers, scientists, innovators and the like have been harnessing the potential of UVC following its effectiveness against other coronaviruses – such as SARS6. For example, in China, buses are being “blasted with UV light” at night-time in an effort to eradicate the virus7; while the People’s Bank of China has “implemented a disinfectant regime which exposes banknotes to UV light and high temperatures in order to sterilise banknotes”.8

So, what do these UV sterilisation devices have in common? Well, the integration of UV Optical Components, of course.

What Optical Components Are Used in UV Sterilisation Devices?

UV Filters

Used across an array of industries for UV-powered applications, our UV Filters are available in the following varieties:

With a wide-ranging portfolio of stock, our UV Optical Filter range spans from 214 to 360nm and from 200 to 2650nm for our metallic-coated ND filters, and are ideally suited to UV sterilisation devices. Alongside our vast range of stock UV Optical Filters, we also offer these components as Custom-Made Optics for seamless integration with your end application.

UV Windows

Common substrates used for protective Windows within UV sterilisation devices include UV Quartz and UV Fused Silica. With a high average transmission of over 80% from 260 to 2500nm, UV Quartz is a popular solution for these applications. Plus, as the substrate is more robust than glass, it’s usually perceived as a durable option. That said, for deep UV, at 175 to 185nm; however, UV Fused Silica is often the more suitable choice of material. Our UV Fused Silica Windows also boast excellent chemical stability, which makes them attractive for sterilisation purposes.

Both options are available from stock (which can also be edged down or re-shaped for projects requiring quick turnaround times) or as custom-made components and are available with Anti-reflective (AR coatings) if needed.

Transmitting well down to 130nm/115nm, >Calcium Fluoride (CaF₂) and Lithium Fluoride (LiF) are two substrates that are frequently employed for a protective window within UV Sterilisation devices.

- Calcium Fluoride (CaF₂) Windows

The Knight Optical range of CaF₂ Windows includes both stock and custom-made options and provides excellent water, chemical and heat resistance. What’s more, for projects requiring swift optical solutions for UV Sterilisation, Knight Optical can edge and resize stock CaF₂ Windows to your specific requirements for quick turnaround times.

- UV

Lithium Fluoride (LiF) is an excellent vacuum ultraviolet (VUV) transmitter and; therefore, is another worthy material for optical transmission windows within these devices. Only available as custom-made optics, Knight Optical’s premium-quality LiF Windows have the option of adding custom protective >optical coatings to ensure high performance and protection against harsh environments that your UV Sterilisation application may endure.

Dispersing Prisms

Covering the UV band down to 175nm, our UV Grade Dispersing Prisms are also a regular component within UV Sterilisers. Known for their ability to refract and deviate the wavelengths of an incoming beam, our prisms are available in two types:

- UV Grade Equilateral Prisms

Our UV Grade Equilateral Prisms are manufactured using UV Grade Fused Silica for use in the UV wavelength from 175nm and are available from stock or as custom-made optics.

- UV Grade Fused Silica Pellin-Broca Prisms

Our UV Grade Fused Silica Pellin-Broca Prisms feature input and output faces at Brewster’s angle for a wavelength of 240nm, which offers exceptionally high transmission for correctly polarised light. Also available from stock or as custom-made components, these UV Grade Prisms also present an option for AR coatings if required.

Why Choose Knight Optical for Your UV Application?

Here at Knight Optical, we have been supplying a range of UV Optical Components for integration with UV Sterilisation Devices – before and after the 2020 coronavirus pandemic. Discerning engineers and scientists working on such devices rely on Knight Optical not only for the premium quality of our output and in-house state-of-the-art Metrology Laboratory’s capabilities but also because – as well as a range of stock UV optics (available for next-day dispatch) – we also offer a sought-after made-to-measure service. When customers opt for custom-made optical components from Knight Optical, not only do they receive fit-for-purpose, project-specific optics, but they can also choose the optical coatings that will enhance their end device. To find out more about our full range of optical coatings for UV sterilisation devices, and other applications, please click here.

If you’re looking for premium-quality, bespoke optical components for your UV sterilisation device, please do not hesitate to get in touch with a member of the Technical Sales Team today.

FOOTNOTES

1https://www.themanufacturer.com/articles/every-uk-manufacturers-helping-to-produce-ppe-and-equipment-for-nhs-workers/

2https://www.who.int/emergencies/diseases/novel-coronavirus-2019/advice-for-public/myth-busters

3https://gamahealthcare.com/latest/will-uv-light-stop-the-covid-19-outbreak

4https://www.bbc.co.uk/news/business-51914722

5https://ultraviolet.com/what-is-germicidal-ultraviolet/

6https://www.sciencedirect.com/science/article/pii/S016609340400179X

7https://metro.co.uk/2020/03/05/buses-blasted-uv-light-rid-coronavirus-12352400/

8https://www.centralbanking.com/central-banks/currency/7509046/will-cash-survive-covid-19