Knight Optical puts Optical Flats in the Spotlight

22nd Oct 2021To coincide with this month’s optics focus, we’re diving into our sought-after range of Optical Flats. In this summarising blog, we’ll explore the main features of these optical components, explain how they work and reveal the customisation elements that are available here at Knight Optical.

Let’s start at the very beginning by answering the layman’s most obvious question – ‘what are Optical Flats’?

As the name suggests, Optical Flats are known for their highly flat surfaces and, in turn, are used as reference components to verify the flatness of optics, such as Windows, Prisms and Filters, for example. Measuring the surface of an optic requires high-precision equipment, which ultimately concludes in high-performing end applications. Therefore, the accuracy of an Optical Flat’s manufacture is of utmost importance.

At Knight Optical, we understand that there’s no one-size-fits-all approach to many technically advanced applications and that, what may be deemed, high-precision for one project may not necessarily apply to another. As such, we offer most optical components in two options – either from stock or as custom-manufactured components, which we’ll explore further in this spotlight article.

How Do Optical Flats Work?

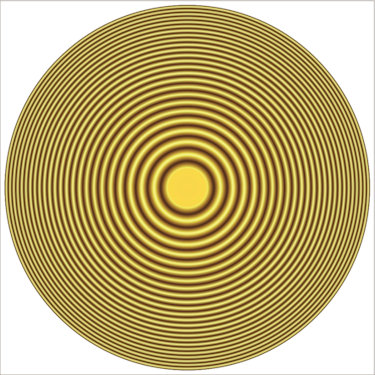

To find out the flatness of an optical component, Optical Flats are placed on top of a polished substrate. Then, by incorporating a monochromatic light source in an arrangement, light bands are formed, known as ‘interference fringes’. The shape of these interference fringes represents the flatness of the component being measured. The number of rings (acknowledged as ‘Newton’s rings’) formed, or the straight profile of the presented lines, indicates how flat the tested part is. Essentially, this is an interference pattern that has been produced by the reflection of light between the two optical surfaces.

Stock Optical Flats

For projects that require swift lead times, we offer a variety of Optical Flats in several dimensions and thicknesses from our stock portfolio – all available for next-day dispatch. Whether you’re after high-quality Quartz or Zerodur® substrates or lambda/10 or lambda/20 surface flatness specifications, our wide-ranging catalogue has something to meet a diverse range of demands. What’s more, we also provide Optical Flats with a surface flatness value of lambda/4, lambda/8 and lambda/16 in short lead times.

Click here to be taken to our stock Optical Flats.

Custom-Made Optical Flats

If your required dimensions aren’t listed, if you need a different flatness value, or you’re looking for an Optical Flat that’s manufactured in a specific material, our custom service may be a more suitable alternative to satisfy your requests. Our custom-made Optical Flats are used for a wide range of reference applications. Typically, bespoke flats are manufactured in a series of sizes, from 25 to 400mm+, with form errors (lambda values) between <1/20 at 633nm (in single or double-sided alternatives). That said, our capabilities are ever-evolving and if you’re looking for something unique, please do not hesitate to get in touch with a member of the Knight Optical team, who can best advise on your requirements and work closely with you to create a project-specific Optical Flat.

Click here to find out more about our custom-made Optical Flats.

Monochromatic Light Units

We also offer Monochromatic Light Units in 110V and 240V choices if you’re looking to complete your setup. These standard moonlight units feature an engraved straight line across the diffused screen, enabling the operator to promptly compare the straight lines of the component being tested, consequently identifying the flatness of the tested component.

Click here to view our units.

Metrology Tested

Our Optical Flats are thoroughly tested on our Zygo Verifire XPZ Interferometer in our state-of-the-art Metrology Laboratory to ensure they meet your precise flatness specifications. Following their testing in our in-house Metrology Laboratory, your Optical Flats will be visually inspected by our hawk-eyed team of QA specialists and packaged within wooden boxes that provide protection whilst the component is not in use.

Why Choose Knight Optical for your Application?

Discerning customers rely on Knight Optical for the premium quality of our output, in-house state-of-the-art Metrology Laboratory, QA Department’s capabilities and our extensive range of Stock and Custom-Made Components.

This year, we’re celebrating 30 years in business. With three decades’ experience under our belt and a whole host of long-standing world-renowned customers on our books, we are proud to have worked on some of the most ground-breaking innovations.

If you are looking for premium-quality optical components, please do not hesitate to get in touch with a member of the Technical Sales Team today.