Stock Available

Bespoke Ordering Available

Contact us now

Find out more about our custom optical flats

Call +44 (0)1622 859444 Call +1 401 583 7846

Knight Optical holds a vast stock of precision optical flats manufactured from quartz and Zerodur® with lambda/10 or lambda/20 surface flatness. These come in both single- or double-sided alternatives.

Optical flats have one, or two, highly polished reference surfaces which are used to determine the flatness of an unknown test or work surface. They are often used in conjunction with a monochromatic light which works predominantly in one wavelength, often with a sodium (589.1nm) or helium (632.8nm) lamp.

We can supply custom optical flats up to 550mm dia. Whether it is different dimensions, flatness, substrate, or the addition of a coating, Knight Optical can assist you with your enquiry. Please note, the substrate material will depend on the application and the desired flatness.

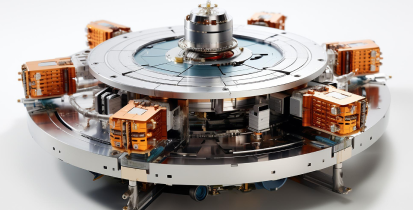

All optical flats are tested on our Zygo Verifire XPZ interferometer to ensure they meet the required flatness specification. Knight Optical can provide an interferogram upon request for reference. Once the precision optical flats have been tested in our dedicated metrology laboratory, they are visually inspected and packaged within wooden boxes that provides protection whilst the optic is not in use.

Speak to our experts about your Custom Optical Flats needs today

Call +44 (0)1622 859444 Call +1 401 583 7846Make a quick enquiry about Custom Optical Flats Now

Dive into the forefront of optical solutions. Got questions about an optical product? Reach out now and let our expertise guide you.

Optical Properties of Optical Flats

Below are our typical manufacturing capabilities, however these are always expanding so please do not hesitate to contact our technical sales team if your individual requirements do not fall within these.

| Dimensions (mm) | 10 to 600mm+ |

|---|---|

| Form Error (lambda) | up to 1/20 @ 633nm (single or double sided) |

| Parallelism (arc mins) | < 5 |

|---|---|

| Scratch/dig | < 60/40 |

Frequently Asked Questions

-

What are optical flats, and how are they used in precision measurement?

-

Optical flats are high-precision, flat surfaces typically made of glass or quartz, used as a reference standard in metrology to measure the flatness of other surfaces. By placing an optical flat on another surface and observing the interference patterns created by monochromatic light, technicians can determine the surface’s flatness with high accuracy. This method is essential in industries requiring precise measurements, such as aerospace, engineering, and manufacturing, to ensure component quality and adherence to specifications.

-

What materials are used to make optical flats, and why?

-

Optical flats are commonly made from fused quartz or optical-grade glass. These materials are chosen for their thermal stability, low expansion coefficients, and transparency to visible light, which are critical for maintaining dimensional stability and accuracy over time and under varying environmental conditions. Fused quartz is especially valued for its high purity and optical clarity, making it suitable for the most demanding metrology applications.

-

How does the price of an optical flat vary, and what factors influence it?

-

The price of an optical flat can vary significantly based on several factors, including its diameter, thickness, material, and the degree of flatness required. Higher precision flats, larger sizes, and those made from materials like fused quartz tend to be more expensive. Additionally, the manufacturing process and quality assurance measures to achieve and verify the specified flatness contribute to the cost. Buyers should consider their application’s specific requirements when comparing prices.

-

What is the difference between an optical flat and an optical flat mirror?

-

An optical flat is a precision instrument used to measure the flatness of surfaces, while an optical flat mirror refers to a mirror with a highly polished, flat surface to a precise optical tolerance. Optical flat mirrors are used in a variety of optical instruments and systems requiring high reflectivity and minimal distortion. Both share the characteristic of having extremely flat surfaces, but their applications in metrology and optical systems differ.

-

Where can optical flats be purchased, and what should buyers look for?

-

Optical flats can be purchased from suppliers specialising in precision optical components and metrology equipment. Buyers should look for suppliers that provide certification of the flat’s precision, material quality, and compliance with relevant standards. It’s also important to consider the supplier’s reputation, customer service, and the ability to offer custom sizes or specifications if required for specific applications.

-

How are optical flats used in metrology to ensure measurement accuracy?

-

In metrology, optical flats are used to perform highly accurate surface flatness measurements. By creating a known reference flatness, they enable the comparison against other surfaces using interference fringes as a gauge. The number, shape, and distribution of these fringes inform the user about the flatness or deviations in the surface being tested. This method is non-destructive and highly precise, making optical flats indispensable tools in settings where surface accuracy is critical.

Is your question not here?

We are ready and waiting to answer any queries you may have about optical flats.

Additional Information

Multiple Features

Optical flats often have the following features:

- One, or two, surfaces polished to a precision flatness.

- High quality surface finish, free from inclusions and bubbles.

- Low coefficient of thermal expansion (CTE).

Material Usage

Various materials can be used for optical flats including fused quartz, fused silica, Zerodur, Clearceram, BK7 and borosilicate. The material used will be dependent on the application, however due to the nature of their use the materials need to be durable but can be polished to a high degree.

Zerodur

Zerodur is a glass-ceramic developed by Schott, and its coefficient of thermal expansion (CTE) is extremely low, making it an ideal material for precision applications, including astronomy and aerospace, where the glass properties need to stay homogenic when there are fluctuations in temperature. The datasheet for Zerodur can be found here.

Coatings

AR Coatings

Antireflective (AR) coatings, including broadband coatings, to optimise the transmission at certain wavelengths or across a range.

Mirror Coatings

Mirror coatings which enable the optical flats to be used as reference mirrors, Knight Optical can coat to a range of different wavelengths.

Capabilities

Get in touch with us:

With our in-house state-of-the-art metrology laboratory you can be confident that your optical components will meet your requirements. You can find out more about our testing facilities here.

Operating for over 30 years

Knight Optical has been operating for over 30 years, with our managing director Colin Overton at the helm. Over this time, we have become a global leader in the production and distribution of scientific optical components and bringing quality into focus for all of our products and services that we provide.

Our 2022/2023 Catalogue

Inside Knight Optical’s catalogue you’ll find details of the industries we serve as well as the many other services we can offer. It also showcases hundreds of our most popular products, supported by useful technical information, to help you choose the right part for your application.

Click below to view our digital catalogue now.