Stock Available

Bespoke Ordering Available

Contact us now

Find out more about our custom silicon optical components

Call +44 (0)1622 859444 Call +1 401 583 7846

Knight Optical supplies high quality silicon optics and associated components, including silicon windows, silicon lenses and silicon prisms, made to your custom specification.

We can offer uncoated and coated silicon optics, including broadband antireflective (BBAR) and diamond-like carbon (DLC) coatings operating at 3 to 5µm (MWIR) wavebands.

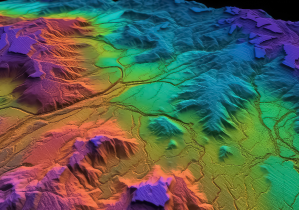

Monocrystalline silicon (Si) stands as one of the most robust optical materials that transmits in the infrared spectrum. Not only is it hard-wearing, but it’s also relatively lightweight, weighing in at just half the density of germanium. This makes it an excellent choice for weight-sensitive optical systems. This material offers an advantageous silicon lens price and the option for silicon aspheric lens designs.

Speak to our experts about your custom optical silicon needs today

Call +44 (0)1622 859444 Call +1 401 583 7846Make a quick enquiry about Custom Silicon Optics Now

Dive into the forefront of optical solutions. Got questions about an optical product? Reach out now and let our expertise guide you.

Optical Properties of Silicon

Silicon offers a multitude of advantages that make it a top choice for optical applications. Among its benefits are its low dispersion and low density, making it ideal for lightweight, high-performance optics systems. Additionally, its excellent thermal stability ensures reliable performance even under varying temperature conditions. To top it off, silicon’s high thermal conductivity further elevates its suitability for applications requiring heat dissipation. Whether you’re considering a standard silicon lens or a more specialised silicon carbide lens, these benefits make for an attractive price and further open the door for silicon aspheric lens designs.

Our typical manufacturing specifications are listed below, however, we are always expanding our capabilities so if your requirements are not mentioned below, please contact our technical sales team who will guide you through your enquiry. A full data sheet of silicon’s optical properties is available here.

| Transmission range | 1.2 to 15µm |

|---|---|

| Refractive Index | 3.4223 @ 5µm |

| Density | 2.33 g/cm3 |

| Melting Point | 1420°C |

| Hardness | Knoop 1150 |

| Diameter | < 5mm to 300mm + |

|---|---|

| Form error (@633nm) | < 0.25 waves |

| Centration /parallelism | < 1 arc minute |

| Scratch/dig | < 60/40 |

| Typical coatings | BBAR @ 3-5µm, DLC @ 3-5µm |

Frequently Asked Questions

-

What are Silicon Lenses and Where Are They Commonly Used?

-

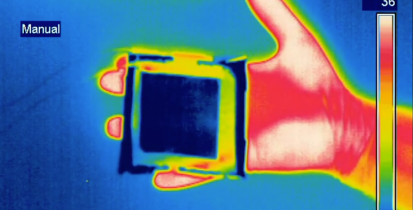

Silicon lenses are optical components manufactured from monocrystalline silicon, a semiconducting material which is transparent in the infrared region, between 1.2µm to 15µm. It also transmits again above 50µm. Due to silicon’s low density and low dispersion, it is often used in weight-sensitive and more compact optical systems, especially in thermal imaging systems and infrared cameras working in the NIR and MWIR regions.

-

How Does Monocrystalline Silicon Differ from Other Forms of Silicon?

-

Monocrystalline silicon is composed of one continuous crystal structure of silicon grown from a seed crystal. This gives optical monocrystalline silicon a high purity. The key difference between monocrystalline silicon and other forms, mainly polycrystalline and amorphous silicon, is their crystal structure and purity.

-

What Are Silicon Optics and What Makes Them Special?

-

Silicon optics are components manufactured from monocrystalline silicon (Si). Silicon optics have some key properties that make them ideal in certain optical applications and systems. This includes transmission in the infrared region, a high refractive index allowing for more compact design, low dispersion which minimises chromatic aberration, and thermal stability. Further, silicon optics come in different types including silicon carbide lenses.

-

Is Optical Silicon Different from Regular Silicon?

-

Yes, optical grade silicon has a higher purity than regular silicon as it is manufactured to have minimal impurities and defects that could affect the optical performance, especially its transmission. Regular silicon, which is often used in electronics and the semiconductor industry, will not have the same level of purity as it is not a critical requirement.

-

How Does the Price of a Silicon Lens Compare to Other Materials?

-

This is dependent on the requirements, but typically lens manufactured from silicon, versus the same specification lens made from germanium, would be more cost-effective. This silicon lens price is due to the abundance of silicon available.

Is your question not here?

We are ready and waiting to answer any queries you may have about (product name).

Additional Information

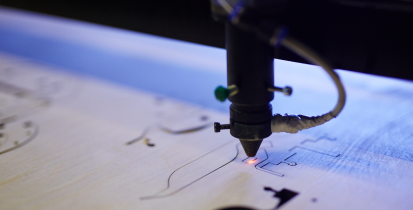

Fabrication methods

Silicon can be fabricated using various methods, notably the Czochralski (Cz) and Float-Zone (Fz) techniques. Using the Czochralski pulling method results in an absorption peak at 9µm due to oxygen presence. However, this is significantly minimised when the Float-Zone technique is employed. Both methods have their own merits and drawbacks, affecting factors such as silicon’s lens price and its quality for silicon optics applications.

Semiconducting nature

Similar to germanium, silicon is a semiconducting material featuring an indirect bandgap of 1.1µm at room temperature. This characteristic can influence its performance in optical systems.

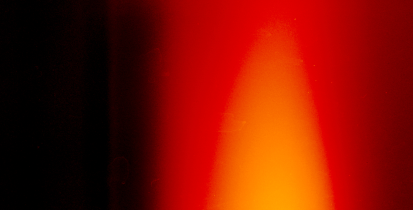

Coating recommendations

Silicon’s transmission hovers at about 50% between 1-6µm, and again above 50µm. For improved performance in silicon optics, an AR coating is advised to enhance transmission. Additionally, a DLC coating can be applied to exposed surfaces for increased durability.

Get in touch with us:

With our in-house state-of-the-art metrology laboratory you can be confident that your optical components will meet your requirements. You can find out more about our testing facilities here.

Operating for over 30 years

Knight Optical has been operating for over 30 years, with our managing director Colin Overton at the helm. Over this time, we have become a global leader in the production and distribution of scientific optical components and bringing quality into focus for all of our products and services that we provide.

Our 2022/2023 Catalogue

Inside Knight Optical’s catalogue you’ll find details of the industries we serve as well as the many other services we can offer. It also showcases hundreds of our most popular products, supported by useful technical information, to help you choose the right part for your application.

Click below to view our digital catalogue now.