Stock Available

Bespoke Ordering Available

Contact us now

Find out more about our custom zinc selenide

Call +44 (0)1622 859444 Call +1 401 583 7846

Knight Optical is your go-to supplier for high quality zinc selenide optical components, tailored to meet your unique specifications. Our product range includes not only ZnSe windows but also ZnSe lenses and prisms.

Whether you’re in need of uncoated or coated ZnSe optics, we’ve got you covered. Whichever you choose, we can offer as a singular custom zinc selenide lens or multiple ZnSe lenses.

Our coatings include broadband antireflective (BBAR) coatings, which significantly enhance the zinc selenide transmission qualities of your custom optical components.

Speak to our experts about your Custom Zinc Selenide needs today

Call +44 (0)1622 859444 Call +1 401 583 7846Make a quick enquiry about Custom Zinc Selenide Now

Dive into the forefront of optical solutions. Got questions about an optical product? Reach out now and let our expertise guide you.

Optical Properties of Zinc Selenide

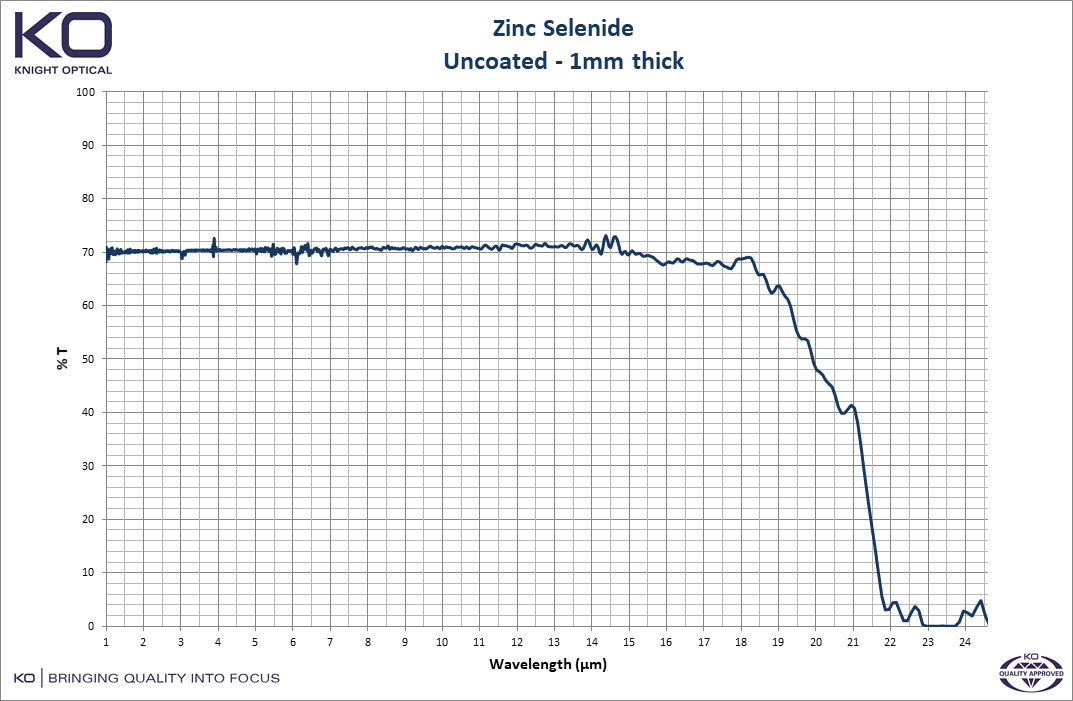

Zinc Selenide (ZnSe) is a noteworthy polycrystalline semiconductor that stands out for its excellent transmission properties. Specifically, it offers about 70% transmission between the wavelengths of 1-15µm and readily transmits from 600nm to 21µm.

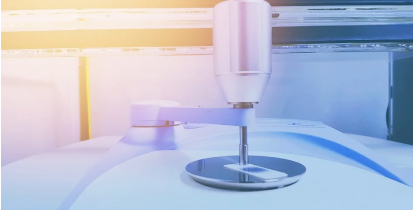

Manufactured through chemical vapour deposition (CVD), ZnSe optics come with a range of impressive characteristics:

- High purity: Ensures minimal impurities in the ZnSe lenses.

- High refractive index homogeneity: Contributes to the high-quality performance of ZnSe lenses.

- Chemically inert: This makes ZnSe particularly stable in various environments.

- High damage threshold: Enables ZnSe optics to withstand intense light or thermal conditions.

- Insoluble in water: Enhances the material’s resilience in humid or wet conditions.

- Highly resistant to thermal shock: Further adds to the durability of zinc selenide lens products.

- Non-hygroscopic: Ensures that ZnSe lenses don’t absorb moisture, thus maintaining their integrity.

- Low bulk loss: Characterised by a low zinc selenide absorption coefficient and zinc selenide absorption spectrum, resulting in minimal loss from absorption and scattering.

All these attributes make zinc selenide glass and optics highly sought-after in various applications.

While we do have a set of typical manufacturing specifications, it’s worth noting that we are continually expanding our capabilities in the realm of ZnSe optics. So, if you don’t see your specific requirements listed, don’t hesitate to get in touch. Our technical sales team is always on hand to guide you through your enquiry and find the perfect zinc selenide lens or other component that meets your needs.

| Transmission range | 0.6 to 21µm |

|---|---|

| Refractive Index | 2.4028 @ 10.6µm |

| Density | 5.27 g/cm3 |

| Melting Point | 1525°C |

| Hardness | Knoop 120 with 50g indenter |

| Operating Temperature | < 250°C |

| Diameter | < 5mm to 100mm + |

|---|---|

| Form error (@633nm) | < 1 wave |

| Centration /parallelism | < 3 arc minute |

| Scratch/dig | < 60/40 |

| Typical coatings | Single sided BBAR @ 2-14µm |

Frequently Asked Questions

-

What is Zinc Selenide and How is it Used in Optics?

-

Zinc selenide is a crystalline material which exhibits high transmission and low absorbance which makes it a popular choice in laser applications such as high-powered CO2 lasers.

-

What are ZnSe Lenses and Why are They Important?

-

ZnSe lenses are optical lenses manufactured from zinc selenide, a polycrystalline material with a transmission waveband that extends from visible through to infrared. This transmission itself secures zinc selenide’s place as an optimal material for CO2 lasers with transmission at both 10.6µm for the CO2 laser, but also at 632.8nm for the accompanying HeNe alignment laser.

-

How Do ZnSe Optics Differ from Other Optical Materials?

-

ZnSe optics are manufactured from zinc selenide, a crystalline material, and are well suited for applications in the infrared region, but unlike some other infrared crystalline materials, such as germanium and silicon, its wavelength range extends into the visible spectrum. The optical material chosen is dependent on the requirements of the specific application they are being used for, all have their own advantages.

-

Is Zinc Selenide Glass Different from Regular Glass?

-

Yes, zinc selenide glass is different from regular glass in areas such as its optical properties, composition, and the applications in which it is used. Unlike regular glass, which is typically amorphous and made from varying materials to achieve specific properties, zinc selenide is made by a crystal growth process.

-

What Factors Affect Zinc Selenide Transmission?

-

The purity of the material can affect zinc selenide’s transmission, and impurities or defects can reduce the transmission as they may absorb or scatter the light. Factors such as temperature and surface quality can also affect the transmission. However, applying a coating can enhance the transmission, especially an anti-reflective (AR) coating.

Is your question not here?

We are ready and waiting to answer any queries you may have about zinc selenide.

Additional Information

Hazardous material

It’s crucial to note that zinc selenide is a hazardous material, and proper safety measures should be in place when handling any ZnSe lenses or other ZnSe components. For detailed information on the safety protocols, you can consult our Zinc Selenide SDS (Safety Data Sheet), which outlines all necessary precautions.

Get in touch with us:

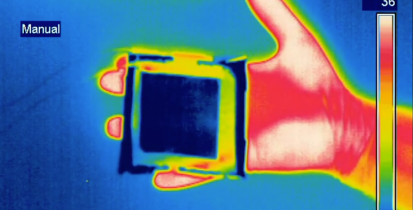

With our in-house state-of-the-art metrology laboratory you can be confident that your optical components will meet your requirements. You can find out more about our testing facilities here.

Operating for over 30 years

Knight Optical has been operating for over 30 years, with our managing director Colin Overton at the helm. Over this time, we have become a global leader in the production and distribution of scientific optical components and bringing quality into focus for all of our products and services that we provide.

Our 2022/2023 Catalogue

Inside Knight Optical’s catalogue you’ll find details of the industries we serve as well as the many other services we can offer. It also showcases hundreds of our most popular products, supported by useful technical information, to help you choose the right part for your application.

Click below to view our digital catalogue now.