Stock Available

Bespoke Ordering Available

Contact us now

Find out more about our custom calcium fluoride

Call +44 (0)1622 859444 Call +1 401 583 7846

Knight Optical supplies high quality calcium fluoride components, including lenses and windows, made to your custom specification. We can offer uncoated and coated calcium fluoride optics, including a broadband antireflective (BBAR) coating.

Calcium fluoride (CaF2) is a crystalline optical material with excellent transmission from UV up to the LWIR region. Different grades of calcium fluoride are available:

- UV grade calcium fluoride has enhanced performance in the UV (and VUV) wavelengths.

- IR grade or standard grade calcium fluoride which performs well in the IR regions.

- Raman Grade which exhibits minimal fluorescence.

Calcium fluoride has numerous beneficial properties including:

- Low absorption

- High refractive index homogeneity

- Chemically inert

- High damage threshold

- Physically stable

- High mechanical strength

- Insoluble in water

For details specs on our IR coatings, please visit our infrared coatings page. Alternatively, you can explore our offerings like UV lenses here.

Our typical manufacturing specifications are listed below, however we are always expanding our capabilities so if your requirements are not mentioned below, please contact our technical sales team who will guide you through your enquiry.

Speak to our experts about your Custom Calcium Fluoride needs today

Call +44 (0)1622 859444 Call +1 401 583 7846Make a quick enquiry about Custom Calcium Fluoride Now

Dive into the forefront of optical solutions. Got questions about an optical product? Reach out now and let our expertise guide you.

Optical Properties of Calcium Fluoride

With our in-house state-of-the-art metrology laboratory you can be confident that your optical components will meet specification, and you can request a full metrology report. You can find out more about our testing facilities here.

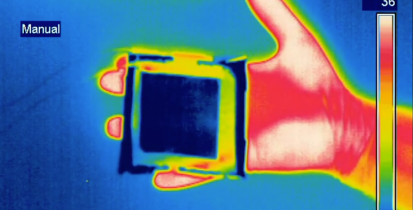

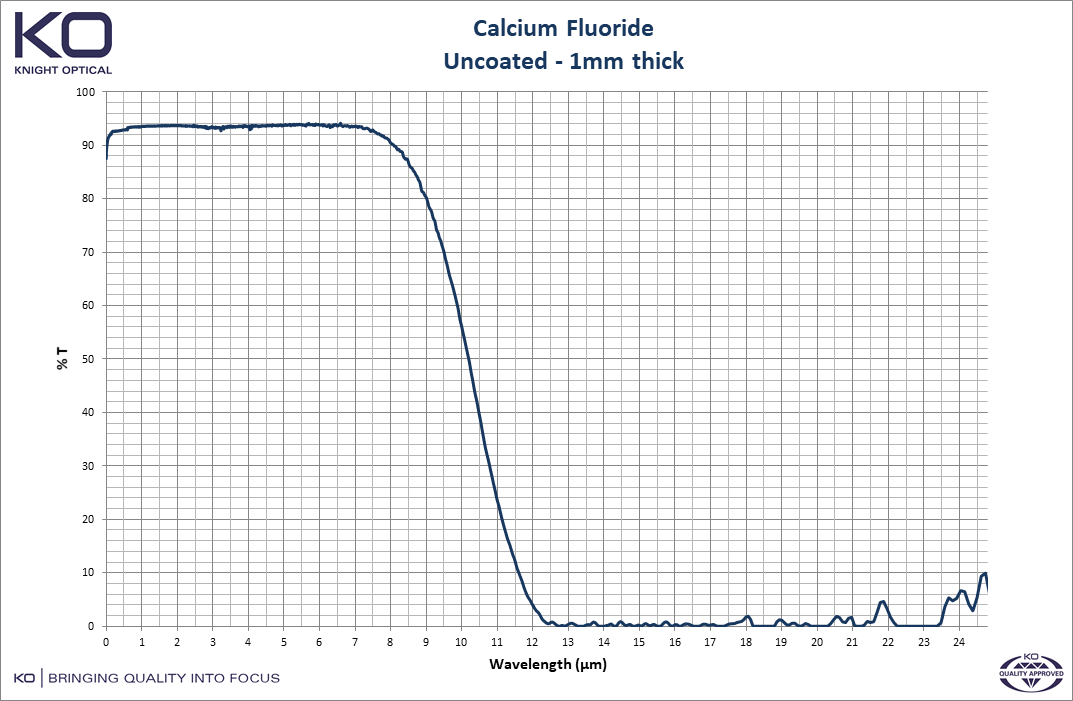

| Transmission Range | 0.13 to 10µm |

|---|---|

| Refractive Index | 1.39908 @ 5µm |

| Density | 3.18 g/cm3 |

| Melting Point | 1360°C |

| Hardness | Knoop 158.3 (100) with 500g indenter |

| Operating Temperature | < 800°C in dry conditions |

| Diameter | < 5mm to 250mm |

|---|---|

| Form error (@633nm) | < 0.25 waves |

| Centration/parallelism | < 1 arc minute |

| Scratch/dig | < 60/40 |

| Typical coatings | AR/AR — T(avg) > 85% @ 3-12µm, AR/DLC — T(avg) > 85% @ 7-14µm |

Frequently Asked Questions

-

What is calcium fluoride, and why is it used in optics?

-

Calcium fluoride is a material known for its unique optical properties, including high transmission from ultraviolet (UV) to infrared (IR) wavelengths. It is widely used in optics for manufacturing lenses, windows, and other components because of its ability to transmit light with minimal absorption. Calcium fluoride’s optical properties are versatile across a broad spectrum, making it ideal for various applications, from UV grade to IR grade optics, catering to diverse industry needs.

-

How does the calcium fluoride transmission spectrum benefit optical applications?

-

The calcium fluoride transmission spectrum is notable for its wide range, extending from the deep ultraviolet through to the infrared region. This broad transmission spectrum allows calcium fluoride optics, such as lenses and windows, to perform exceptionally in applications requiring high precision and minimal light loss. Its excellent transmission capabilities make it a preferred choice for high-performance optical systems in research, laser, and imaging applications.

-

What are the differences between UV grade calcium fluoride and IR grade calcium fluoride?

-

UV grade calcium fluoride is optimised for applications requiring high transmission in the ultraviolet spectrum, making it suitable for UV light sources and instruments. IR grade calcium fluoride, on the other hand, is tailored for infrared applications, where it excels due to its low absorption and high transmission in the IR spectrum. The choice between UV grade and IR grade depends on the specific wavelength range and performance requirements of the optical system.

-

What is the significance of calcium fluoride birefringence in optical design?

-

Calcium fluoride exhibits very low birefringence, making it an excellent material for optical components where polarisation sensitivity is critical. Low birefringence ensures that light can pass through the material without significant polarisation distortion, which is crucial for applications in polarised light microscopy, laser optics, and high-precision instrumentation. This property enhances the performance and reliability of optical systems by maintaining the integrity of polarised light signals.

-

How does the calcium fluoride refractive index influence optical component design?

-

The refractive index of calcium fluoride is a critical parameter in optical design, influencing how light bends or refracts when entering the material. With its relatively low refractive index, calcium fluoride components can minimise optical aberrations, leading to clearer and more accurate imaging. This makes calcium fluoride lenses and windows ideal for applications requiring high precision, such as telescopes, microscopes, and photographic lenses.

-

Can calcium fluoride optics be used across UV, visible, and IR spectrums?

-

Yes, calcium fluoride optics are versatile and can be used across UV, visible, and IR spectrums due to their broad transmission range and excellent optical properties. Whether it is a calcium fluoride window or lens, these components offer superior clarity and performance across a wide range of wavelengths, making them suitable for a diverse set of applications from scientific research to industrial imaging and laser systems.

Is your question not here?

We are ready and waiting to answer any queries you may have about calcium fluoride.

Additional Information

Calcium Fluoride Production

Calcium flouride is grown by the vacuum Stockbarger technique using either naturally mined or chemically prepared fluorite dependent on the grade.

Laser Lens Substrate

Due to its high refractive index homogeneity and low absorption, calcium fluoride makes an ideal substrate for lenses used in high-performance laser systems. The high homogeneity means there will be minimal scattering and deformation of the wavefront.

Apochromatic Lens Use

It is traditionally used in an apochromatic lens design, which generally consists of a fluoride lens and two other elements. Apochromatic lenses can correct for both chromatic and spherical aberration, due to this they are widely used in photography where the designation ‘APO’ is used.

Considerations

High Temperature Limit

In dry temperatures CaF2 has a maximum operating temperature of 800°C.

Degradation Temperature

Calcium fluoride is not readily degraded under normal atmospheric conditions until 600°C where it will start to soften.

Thermal Shock Vulnerability

It is vulnerable to thermal shock at high temperatures.

Docs & drgs

Available Stock

Get in touch with us:

With our in-house state-of-the-art metrology laboratory you can be confident that your optical components will meet your requirements. You can find out more about our testing facilities here.

Operating for over 30 years

Knight Optical has been operating for over 30 years, with our managing director Colin Overton at the helm. Over this time, we have become a global leader in the production and distribution of scientific optical components and bringing quality into focus for all of our products and services that we provide.

Our 2022/2023 Catalogue

Inside Knight Optical’s catalogue you’ll find details of the industries we serve as well as the many other services we can offer. It also showcases hundreds of our most popular products, supported by useful technical information, to help you choose the right part for your application.

Click below to view our digital catalogue now.