Stock Available

Bespoke Ordering Available

Contact us now

Find out more about our custom beamsplitters

Call +44 (0)1622 859444 Call +1 401 583 7846

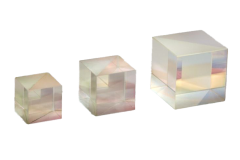

Knight Optical excels in providing custom optical beamsplitters that operate across various wavebands, including UV, visible, and IR spectra. Whether you require plate beamsplitters or cube beamsplitters, we can manufacture these to align perfectly with your spectral and dimensional needs.

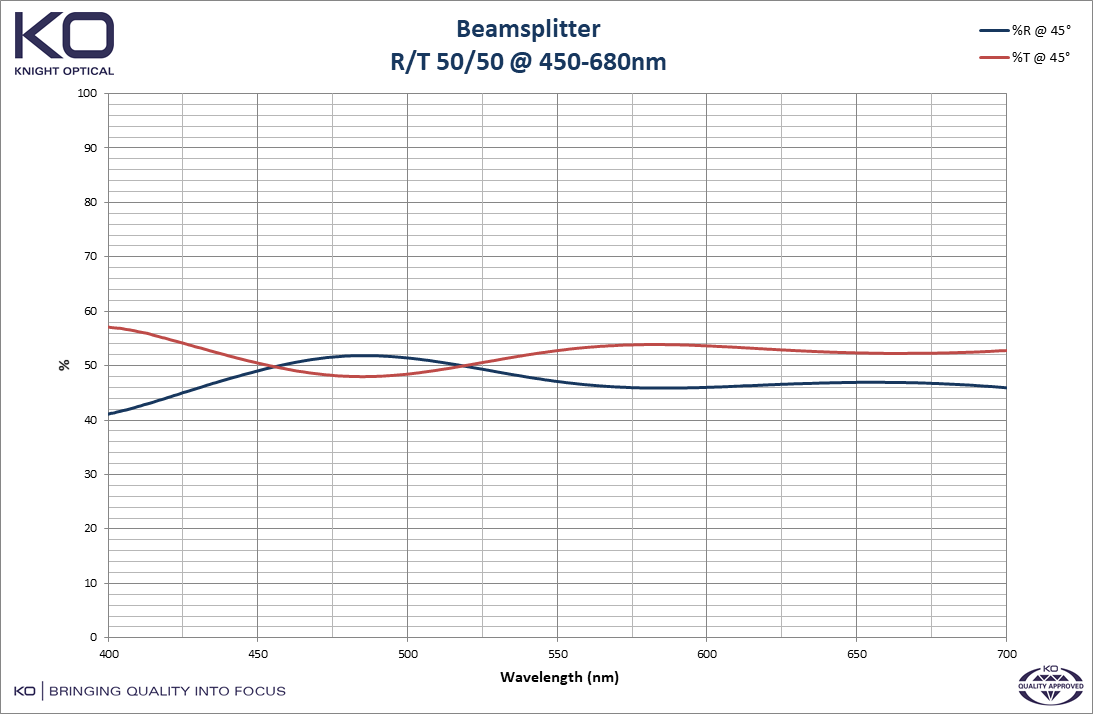

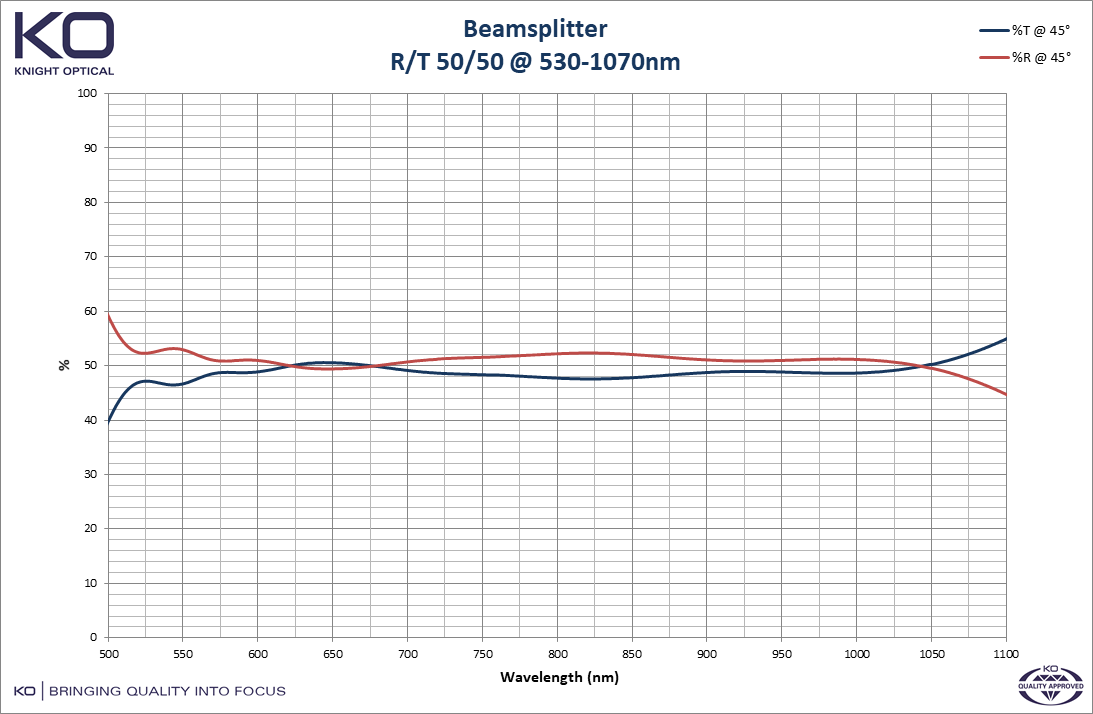

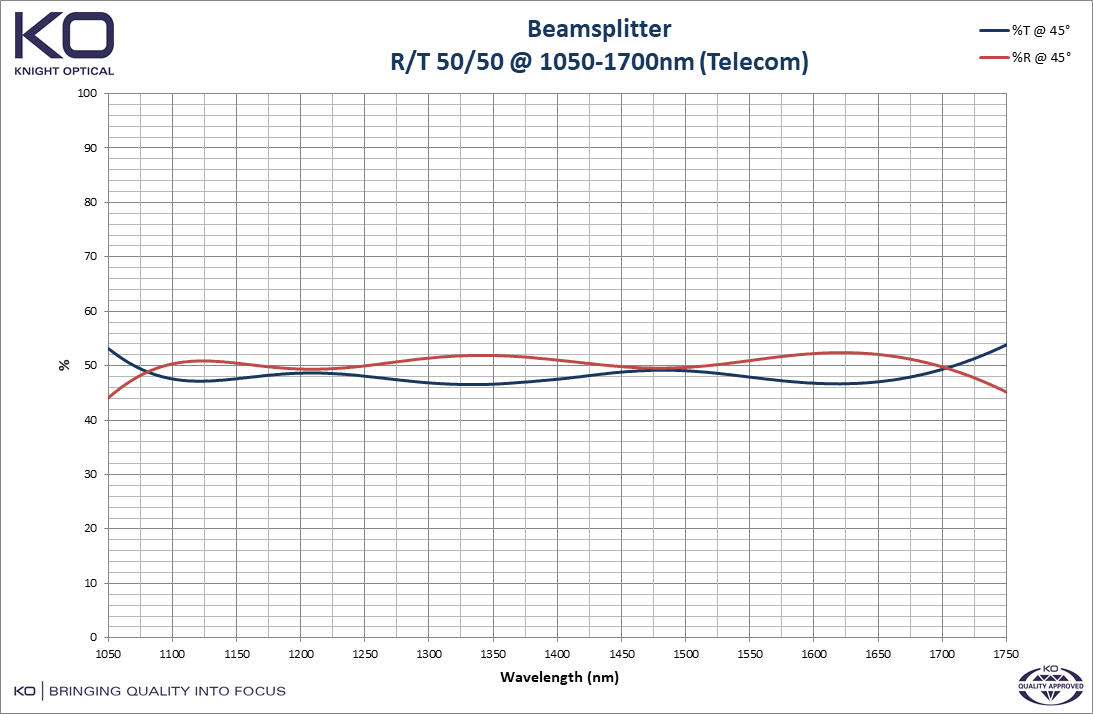

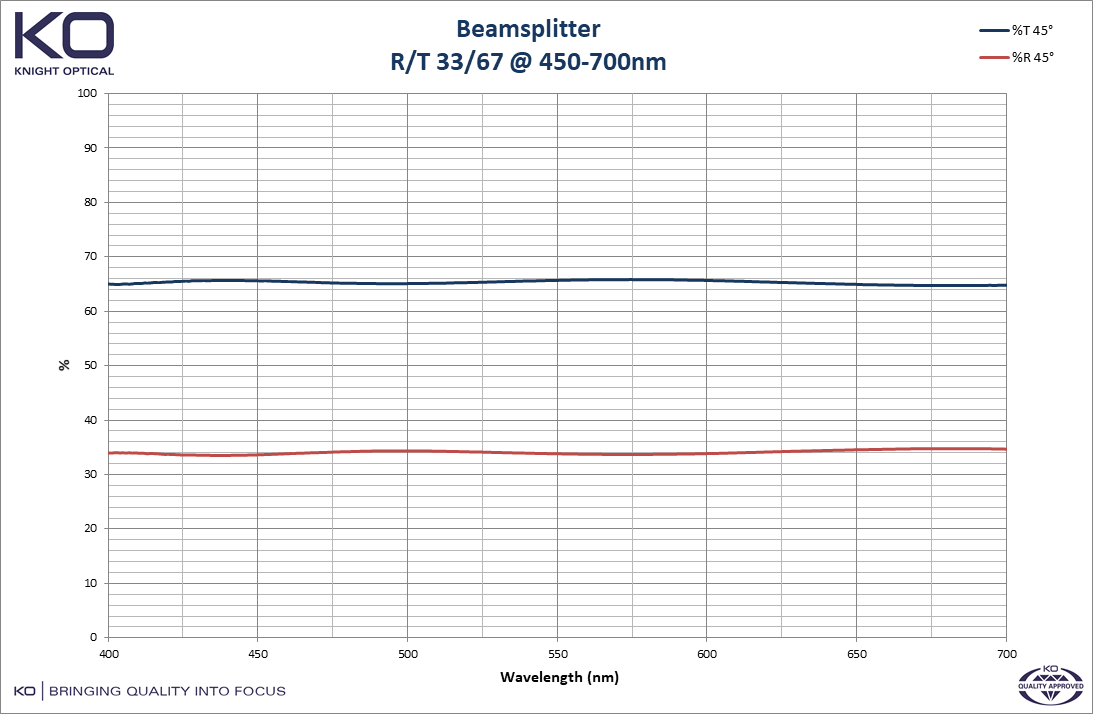

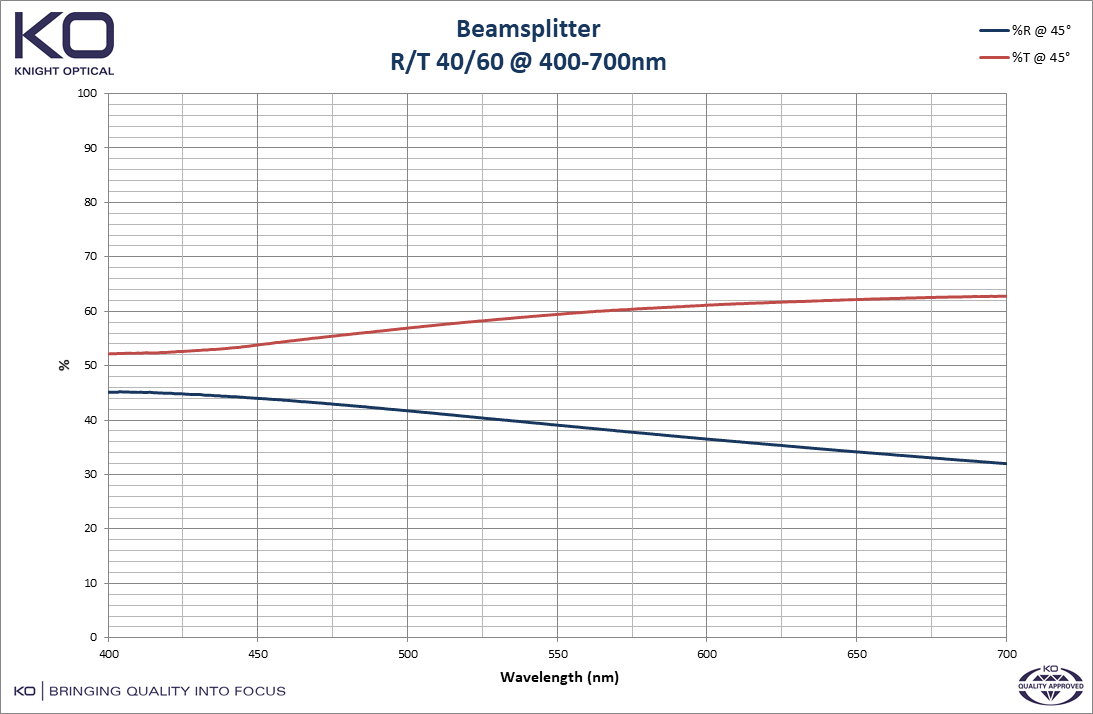

For diverse applications, we offer both polarising beam splitters and non-polarising beamsplitters in plate and cube configurations. A standard non-polarising beamsplitter cube is meticulously engineered to divide the incoming light beam based on a predetermined reflection/transmission (R/T) ratio, such as a balanced 50/50 split, or more tailored splits such as 10:90, 20:80, and 30:70. Knight Optical can adapt the beam splitter material and coatings to provide an R/T ratio that seamlessly integrates with your specific application.

Knight Optical stock a range of 50:50 and 30:70 plate beamsplitters which operate in the visible and NIR wavelengths. To ensure optimal performance, the rear surface of our beamsplitters have an applied AR coating to prevent double reflections.

If you’re looking to split light beams based on their polarisation states, our polarising beamsplitters are your ideal choice. These are designed such that S polarisation gets reflected while P polarisation passes through, all achieved with a high extinction ratio (Tp:Ts).

In addition to these, Knight Optical can also cater to more specialised needs by providing unique types of beamsplitters like polka dot and dichroic beamsplitters.

Speak to our experts about your Custom Beamsplitter needs today

Call +44 (0)1622 859444 Call +1 401 583 7846Make a quick enquiry about Custom Beamsplitters Now

Dive into the forefront of optical solutions. Got questions about an optical product? Reach out now and let our expertise guide you.

Coatings

For a quick turnaround on custom dimensions, Knight Optical holds a stock of beamsplitter sheet material with the following coatings:

Frequently Asked Questions

-

What are Optical Beamsplitters and How Do They Work?

-

An optical beamsplitter is a component that splits an incident light beam into two or more separate beams. These are usually defined by their transmission intensity or polarisation.

-

What’s the Difference Between a Polarising Beamsplitter and a Non-Polarising Beamsplitter Cube?

-

The main difference between a Polarising Beamsplitter and a Non-Polarising Beamsplitter is how they interact with polarised light. A polarising beamsplitter (PBS) will have a polarising coating that is designed to transmit a specific polarisation state whilst reflecting the other, therefore separating light by its polarisation. These are often used in laser systems. A non-polarising beamsplitter, typically a non polarizing beam splitter cube, does not alter the polarisation state of the incident beam, instead, it is designed to transmit and reflect specified portions of light, regardless of whether it is unpolarised or randomly polarised. These are generally used in interferometry.

-

What Materials are Commonly Used for Beamsplitters?

-

The beam splitter material used depends on the application requirements, such as the desired wavelength range. Typically N-BK7, fused silica, or float glass, are used for applications using visible wavelengths. Birefringent crystalline materials are also used, such as calcite and quartz, which act as polarising beamsplitters.

Is your question not here?

We are ready and waiting to answer any queries you may have about beamsplitters.

Additional Information

Plate beamsplitter

It’s important to highlight that plate beamsplitters, operating at a 45° angle of incidence (AOI), display a shift in the transmitted beam. This deviation is influenced by both the thickness and the refractive index of the beam splitter material used. Such shifts can pose challenges for precise alignment in certain applications.

Cube beamsplitter

A cube beamsplitter is often more straightforward to incorporate into optical systems and presents minimal deviation in the transmitted beam. This makes it a favourable choice for applications requiring precise alignment. These beamsplitters can be either a polarising or non polarizing beam splitter cube.

Crystalline polarising beam splitter types

Crystalline birefringent substances serve as an effective type of polarising beam splitter, with Wollaston prisms and Glan-Taylor prisms being prime examples. In the case of a Wollaston prism, which is usually comprised of a pair of calcite prisms, both linearly polarised beams pass through the exit face with minimal disturbance.

Germanium in infrared

Germanium serves as a natural 50/50 beam splitter in the infrared wavelengths, specifically in the 2 to 14µm wavelength range, owing to its elevated refractive index. This makes it an ideal choice for applications within the infrared spectrum.

Quality Assurance

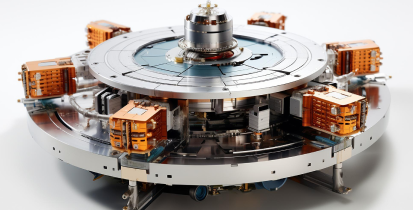

Spectral scanning capabilities

Transmission and reflection scans are performed using our Agilent Cary 7000 Spectrophotometer. This advanced instrument can execute spectral scans at various angles of incidence and diverse polarising and non-polarising states. Additionally, we can supply you with ASCII data and graphs to suit your analytical needs.

Zygo Verifire testing

When it comes to ensuring the quality of optical beamsplitters, flatness and irregularity are scrutinised using our Zygo Verifire XPZ interferometer. This advanced testing equipment allows us to evaluate the transmitted wavefront error as well, ensuring the highest standards of optical performance.

Parallelism accuracy

Parallelism of our optical beamsplitters is rigorously verified using our Trioptics PrismMaster, which boasts an accuracy level of up to 3 arc seconds. This ensures that the components you receive are of the highest calibre.

Infrared component testing

Additionally, we have the capability to evaluate infrared optical components using our Agilent Cary 660 FTIR spectrometer. This allows us to deliver components that meet stringent requirements, ensuring optimal performance in your infrared applications.

Quality inspection standards

Before packaging, all optical beamsplitters and other components undergo a 100% visual inspection. Our highly trained staff adhere to ISO 10110 and MIL-0-13830A standards. They are equipped to identify imperfections down to a 10/5 scratch/dig level, a crucial factor particularly in laser applications.

Capabilities

Available Stock

Get in touch with us:

With our in-house state-of-the-art metrology laboratory you can be confident that your optical components will meet your requirements. You can find out more about our testing facilities here.

Operating for over 30 years

Knight Optical has been operating for over 30 years, with our managing director Colin Overton at the helm. Over this time, we have become a global leader in the production and distribution of scientific optical components and bringing quality into focus for all of our products and services that we provide.

Our 2022/2023 Catalogue

Inside Knight Optical’s catalogue you’ll find details of the industries we serve as well as the many other services we can offer. It also showcases hundreds of our most popular products, supported by useful technical information, to help you choose the right part for your application.

Click below to view our digital catalogue now.