How Optics are Revolutionising Engineering & Manufacturing Processes

23rd Jan 2019Manufacturing and engineering have been revolutionised by the use of optics, both in terms of production and control. There are many benefits to the use of optics in manufacturing, with host of optical techniques employed across a variety of industry sectors, many of which are critical to the production of everything from highly complex instruments to everyday necessities.

In this article, we are exploring the use of optics in engineering and manufacturing and their role in enhancing capabilities and enabling new processes. We’ll be revealing some of the most popular optical instruments and applications, whilst taking a look at the way they have transformed so many aspects of manufacturing and engineering.

How are optics used in manufacturing?

Optical techniques are in use across many aspects of manufacturing. They can be broken down into two core areas:

- Manufacturing production

One of the most extensively used optical technologies in manufacturing production is laser. Lasers are widely used for cutting, drilling and welding a huge variety of products and components throughout numerous industry sectors.

They are also a vital component in lithography, used in microfabrication and 3D printing.

These are all processes we will take a more detailed look at a bit further on.

- Manufacturing control

The monitoring and control of manufacturing processes and of the products that are being engineered is a crucial aspect of production.

Optics are used extensively to monitor chemical processes, to check for features and defects and to verify positioning, dimension, composition and alignment. Lasers are employed to efficiently measure distance and shape to ensure compliance with the specification.

Optical techniques used in engineering and manufacturing

Let’s take a closer look now at some of the most popular optical techniques in use across various industry sectors, along with the many advantages they provide.

The use of optical technology varies from one industry sector to another. Some of the heaviest users include construction, aviation and aerospace, automobile, medical, chemicals and semi-conductor. This is by no means a limited list however as the use of optics is vast.

Lithography for microfabrication and 3D printing

Earlier we touched upon the use of lithography in microfabrication. Also known as optical lithography or UV lithography, this process utilises ultraviolet lasers and is crucial to the production of literally thousands upon thousands of items, many of which we use every day such as smartphones and computers. In short, anything that requires a printed circuit board or microprocessor will have been party to lithography.

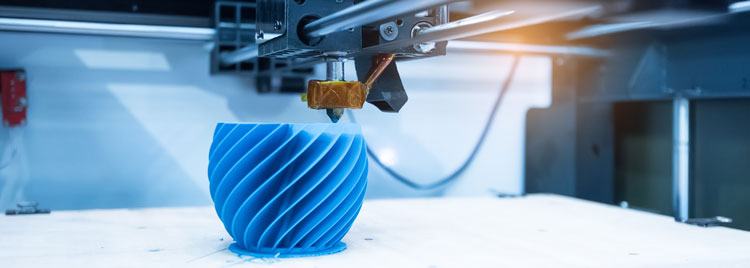

A variation of the process, known as stereolithography, is used in 3D printing to produce the likes of prototypes, patterns, models and production parts; all essential to the manufacturing process and of vital use in medical environments.

Laser cutting, drilling and welding

Lasers have for the most part replaced traditional production methods and are now used widely for cutting, drilling and welding, with many benefits.

Laser cutting machines generally work faster and produce a higher standard of cut than conventional cutting devices. They also use less energy when used to cut certain materials, such as aluminium and steel.

Laser drilling is a vital aspect of manufacturing processes for an array of industries and applications around the world. Laser drilling is a clean, non-contact process suited to a wide range of materials. The precise nature of laser drilling means results are exceptionally accurate and consistent with the drilled material being left perfectly intact. The aerospace, automotive, medical, electrical, solar and semiconductor industries use laser drilling widely.

Laser welding is well known for producing welds of superior strength compared to traditional welding. For quality and for cost efficiency, a laser is the preferred welding method. Used heavily in high volume industries such as the automotive and manufacturing sectors, laser welding is particularly suited to repetitive or continuous welding operations and it integrates seamlessly into other processes. The process guarantees consistent accuracy and offers the ability to tackle even the most complex requirements and reach challenging places. What’s more, laser welded joints are perfectly uniform and aesthetically appealing.

Optical sensors

Optical sensors allow reliable, accurate measurements to be taken so that manufacturing and engineering processes can be effectively and, where necessary, automatically monitored and controlled.

Monitoring can be undertaken without contact, in real time, and at exceptionally rapid rates, making the whole process attractively cost and time effective. Optical sensors are used widely in the automotive, packaging and pharmaceutical manufacturing sectors to name just a few.

Inline inspection with the use of robot-guided optical sensors makes it possible to inspect and measure parts on a production line without any interruption to the production cycle.

Light barriers – devices that detect human presence around potentially hazardous moving machinery – are another major innovation in manufacturing, playing a vital role in health and safety.

In summary, optical sensors offer possibilities that cannot be achieved by any other means.

Machine vision

Machine vision helps to solve complex industrial tasks. It is a consistent and reliable method that uses digital sensors within industrial cameras with specialist optics to acquire images.

Machine vision allows the processing, analysis and measurement of a range of characteristics in production. These characteristics are then set against a pass-fail response based on pre-set parameters. Where discrepancies are detected, automated responses come into play, such as the rejection of an incorrectly weighted item from a production line.

Machine vision is also used to take real-time measurements on production lines to ensure all components and fittings are in alignment.

Metrology

Metrology is a vital optics-led element of measurement and control in engineering and manufacturing. Without metrology, the precision specifications that are crucial to the effectiveness and safety of any product that comes off the production line would be at risk.

Machinery is a moving entity. Over time, parts shift, misalign or lose efficiency. Even minor discrepancies can lead to significant problems. Metrology is the solution used to ensure critical measurements are completely accurate. Precision is vital in a range of industries, especially the aerospace, automotive and technology sectors.

Metrology instruments are able to take measurements within a millionth of an inch. The adoption of precision metrology has significantly improved the quality of many products.

“Optics play a vital role in manufacturing and engineering”

It is clear to see the vital role optics play across the entire manufacturing spectrum and how things have changed considerably since their introduction. With optical innovations advancing all the time, things can only get better.

In our next post we’ll be delving a little deeper to take a look at how the optical components relied upon by engineering and manufacturing optical instruments and applications, such as longpass colour glass filters, plane mirrors, UV fused silica and sapphire and aspheric lenses, can be custom engineered to meet the demands of the environments in which they are used, and the critical reliance that is placed upon them.

Optical component specialists for the engineering and manufacturing sector

Knight Optical has been specialising in the custom design of precision optical components for almost three decades. Our technical expertise across all aspects of optical component design and manufacture, and our commitment to innovating and early adoption of pioneering ideas place us in the strongest position possible to support the success of our valued customers.

Should you wish to discuss your individual optical component requirements for any engineering or manufacturing applications, our experienced, multilingual sales team and industry trained technical experts are at your full disposal.