How is Energy Created from Wind Turbines, and how are Optical Components Involved?

27th Jun 2019In September 2018, it was announced that the UK’s wind generation capacity had surpassed 20 Gigawatts for the first time, equating to enough energy to meet the annual power needs of over 14 million homes. The news followed the opening of the world’s largest 189-turbine wind farm off the Cumbrian coast in the same month.

The energy production capacity of wind in the UK has meant that the nation’s CO2 emissions have been reduced by more than 25 million tonnes per year thanks to the move away from fossil fuels.

It has been common knowledge for some time that there is a significant need for alternative energy sources, and wind energy is clearly having a considerable impact.

The subject of how energy is created from wind turbines is an interesting one and, what is even more interesting, is the way in which wind energy has advanced over the years, with turbine output efficiency having been greatly enhanced. The technology behind this advancement is optics-led, so let’s take a closer look at the vital relationship between optics and wind energy.

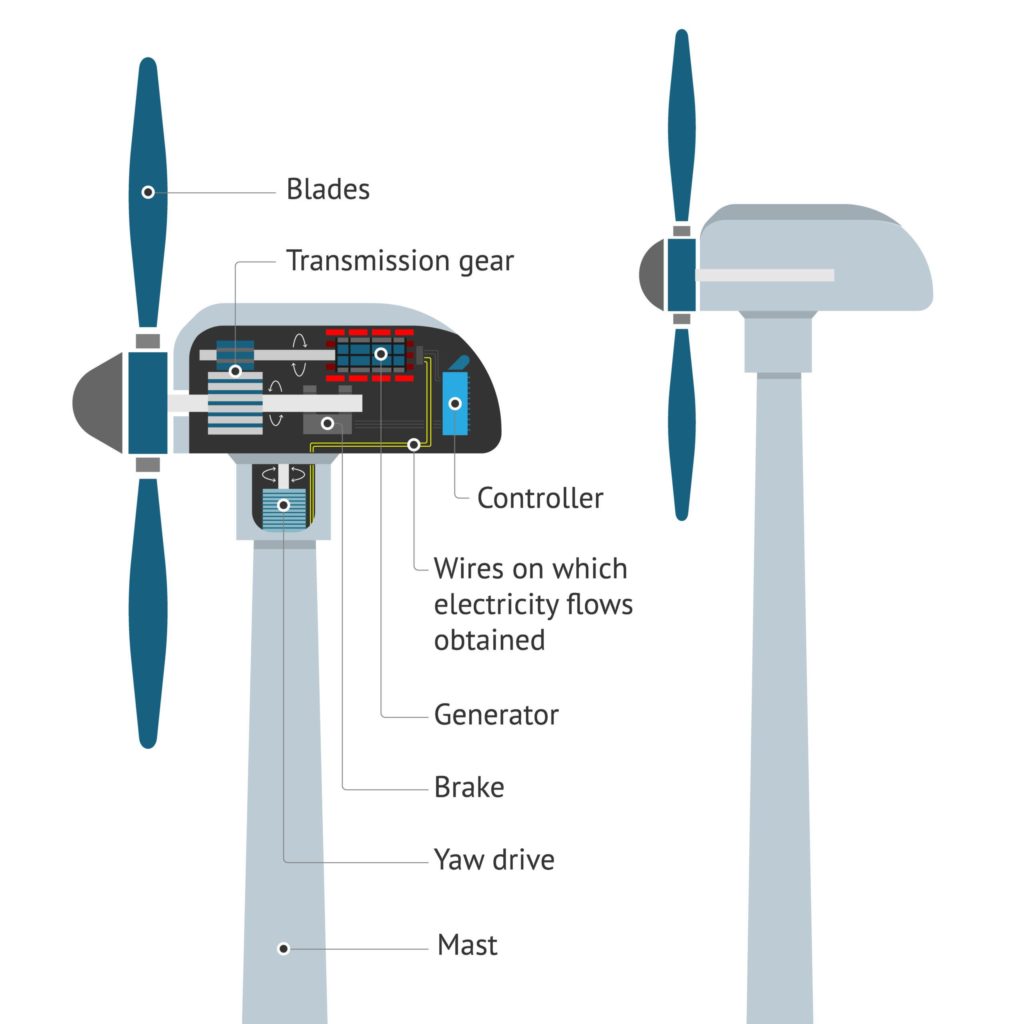

How do wind turbines create energy?

How much energy do wind turbines create?

The faster the wind blows, the more electricity is generated, although if the wind is too strong then the turbine will shut itself down so that it does not become damaged.

Most onshore wind turbines can create around 2-3 megawatts of energy, equating to more than 6 million kilowatt hours of electricity per year, meeting the electricity demands of around 1,500 households.

In 2018, approximately 15 per cent of the electricity generated in the UK came from wind power, a marked rise from just 7 per cent in 2013. As of April 2019, there are 1,932 offshore turbines in the UK, and 7,779 onshore. [1]

Siting wind farms is quite a science. Because energy production is completely dependent on the wind levels, the farms need strategic planning to ensure they are in locations that provide a reliable source of wind throughout the year. Wind turbine efficiency is also crucial to the energy production volume. Interestingly, both the siting of wind farms, and turbine efficiency, are dependent on optical technology.

How is optical technology involved in wind energy?

Much of the advancement in wind energy can be attributed to the evolution of optical technology which has made it considerably more straightforward and safer to monitor the structure and components of the wind turbine. This monitoring allows potential failures to be detected in advance; it reduces operational risk through early identification of damage, and validates wind farm siting plans and new turbine design.

LiDAR

Light detection and ranging (LiDAR) is a ground-breaking optical technology. It works by sending a pulse of light and then waiting for it to return, measuring the time taken and recording the data.

LiDAR systems are widely used to monitor wind speeds and directions. They provide highly advantageous intelligence when planning a wind farm site. From deciding whether a particular site will deliver optimal energy, through to the precise positioning of the turbines, LiDAR plays a pivotal role.

Once turbines are in place, LiDAR takes on a new and again very important role: it becomes responsible for maximising output efficiency.

With the LiDAR system mounted to the nacelle of the turbine, the adjustment of the blades becomes an automated, straightforward process. The system has the ability to sense the wind before it meets the blades, predicting wind direction, turbulence and gusts, all allowing for beneficial productivity increases.

LiDAR technology has made it possible to measure wind faster, further and higher than the traditional met masts used in the past. It has also lowered the costs of collecting data, and has boosted its accuracy. LiDAR can also be used to monitor gearbox or bearing failures; blade deterioration and unbalanced systems. It is a truly valuable optical technology.

What optical components are typically used in wind energy monitoring systems?

LiDAR systems are made up of high precision optical lenses, front coated mirrors, cover windows and dome windows.

Precision grade lenses speed up the collection of data through the system and ensure the highest levels of accuracy. Front coated mirrors are responsible for steering the laser beam of the LiDAR device. Cover windows protect the vital components of the LiDAR system, and dome windows, highly durable optical windows consisting of a pair of parallel curved surfaces, offer exceptional strength in high pressure environments.

What to consider when selecting optical components for optical wind monitoring instruments?

The durability and reliability of a LiDAR system is crucial if wind energy is going to benefit from its monitoring, but it must be considered that these monitors have to operate in exceptionally harsh environments.

Wind monitoring LiDAR systems, mounted to the nacelle of a wind turbine, are subject to the effects of altitude and grit, both of which have the potential to negatively affect data accuracy. The importance of selecting optical components customised to withstand such severe effects cannot be stressed enough.

Results must be pinpoint-accurate, regardless of the conditions. Optical components must therefore be engineered with the highest levels of precision for swift, flawless data collection.

Robust materials like sapphire, UV grade fused silica, quartz and toughened borosilicate make a considerable difference. The addition of anti-reflective coatings enhances transmission, whilst hydrophobic coatings can reduce the impact of air pollution.

Custom Designed Optical Components for Wind Monitoring Technology

Knight Optical is a globally respected name in the field of optical component design and a long term supplier to the energy optics sector. Our technical experts work closely with monitoring instrument manufacturers to custom engineer optical components specifically for use in the harsh, high altitude environments connected with wind monitoring equipment. Our cutting-edge metrology laboratory ensures all components are precision tested to meet exacting specifications for the ultimate guarantee of accuracy and reliability where it is so incredibly important.

For tailored advice on LiDAR optical components from our multilingual technical sales team please call 01622 859444 or email us at [email protected].