3D Scanners: Why Precision Accuracy is Crucial, and How to Achieve it

20th Mar 20193D laser scanning uses LiDAR or phase-based technology to capture three dimensional data across a range of settings. Precise, clear data is fed back from the scanners via millions of measurement points which together form ‘point clouds’. Because the points are intricately detailed, it makes it possible to derive an exact measurement, in real time, regardless of surface features or size.

3D laser scanning first came into the public eye during the Apollo 15 lunar mission where it was used to create a surface map of the moon which NASA then used to craft a 3D model of the moon’s surface in 2011. It is now the measurement system of choice across many industries and used in an array of settings.

What are the uses of 3D scanners?

With the ability to measure height, volume and cross section, 3D scanners play a vital role across a multitude of settings, and offer various benefits.

Here are just some of their uses:

- Condition surveys

- Power network surveys

- Safety surveys

- Three dimensional product line inspection for quality control and safety

- Construction sequencing, scheduling and simulation

- Design engineering

- Prefabrication

- Architectural and archaeological surveys

- Geographical data collection

- Virtual design and construction

- Collision protection in autonomous vehicles

What are the benefits of 3D scanners?

3D laser scanning offers a multitude of benefits:

- Speed – laser scanners have the ability to capture up to a million data points per second, relaying information back in record time.

- Accuracy – the error margin of the traditional measuring device is overridden by the laser scanner which is considered the most accurate method of measuring currently in use, accurate to sub-micron level. The depths of detail that can be derived from the vast number of data points are unsurpassed by any other measurement method.

- Cost saving – pre-project laser scanning assures comprehensive and accurate information from the outset resulting in effective cost planning and waste reduction.

- Comprehensive – all the data you need, including data you didn’t know you needed, can be captured with a 3D laser scanner. So there is never any need to return for forgotten measurements.

- Safe – there is no need to put anyone at risk when taking measurements using laser scanning technology; even the most hazardous locations can be surveyed in total safety.

The importance of accuracy

For a measurement system to be able to guarantee the levels of accuracy that users have come to demand, its optical components have to do the same. Accuracy can be affected by environmental conditions, so laser optical components must be designed to withstand a range of atmospherics such as extremes of temperature, humidity, bright light, chemicals and pollution.

It is possible to engineer optical components so that they deliver the highest possible performance, in turn ensuring the laser application is able to do the same with complete reliability.

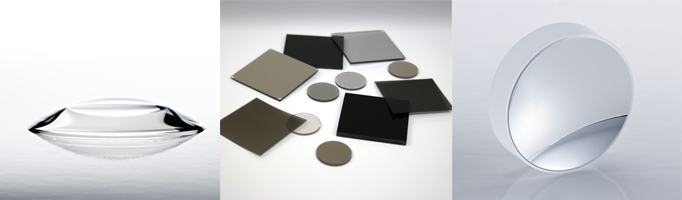

Condenser lenses for example are typically made from Borofloat which offers excellent thermal expansion properties. These light concentrating lenses can be further toughened to cope with harsh environments.

Achromatic doublet lenses optimise performance and reduce chromatic and spherical aberration for exceptional accuracy in laser scanning technology.

Meniscus lenses of laser grade are crafted from high index material and designed to minimise spherical aberration for the ultimate in data point accuracy.

Aspheric lenses can be thermally toughened to stand up to high temperatures. They play an important role in correcting spherical aberration and can replace multi-lens systems with a single lens where space is at a premium.

High index planoconcave lenses are coated on both faces with antireflective magnesium fluoride for optimum performance when controlling laser beams in a range of conditions.

Optical windows of precision grade are crafted from materials suited to harsh environments. Performance is guaranteed through tightly controlled flatness and surface quality.

Dielectric coated mirrors increase system performance by reducing energy loss. They also play a crucial role in precision alignment applications.

Neutral density filters are used widely in laser applications where extreme levels of light can damage other optical components or reduce the accuracy of results. They reduce transmission evenly by absorbing or reflecting the light that is not being transmitted.

The importance of metrology

We have ascertained the importance of precision accuracy when it comes to 3D laser scanning optics, which means precision testing is absolutely crucial.

At Knight Optical we place extreme importance on ensuring all our customers’ specifications are complied with to the minutest degree of exactness. We have invested considerably in procedures, systems and state-of-the-art optical testing instruments which, together with our team of skilled metrology technicians, allow us to guarantee that every component that leaves our premises does so in strict accordance with requirements.

In addition, our in-depth understanding of laser applications means we are able to work closely with our customers to engineer custom optical components that meet the many challenges met by 3D scanning applications.

3D Laser Scanning Optical Components from Knight Optical

For tailored advice on all your 3D laser scanning optical component requirements from our helpful multilingual technical sales team please call 01622 859444 or email us at [email protected].