Optics for Oil & Gas

Offshore oil and gas industry benefits our lives in many ways. The products that are used have formed the society we live in today from supplying energy to industry and homes to powering our transportation vehicles. Systems used to monitor oil and gas production use specialist optical components function. Knight Optical has been supplying optical components to the oil and gas industry for over 25 years and continues to build its supply chain in a highly demanding industry. These include;

- Optics for combustion analysers

- Optical filters for gas detection

- Optics for continuous emission systems (CEMS)

- Optics for environmental monitoring

- Optics for oil in water analysis

- Optics for infrared systems

Custom Optic Solutions

Knight Optical are global leaders in custom optical solutions. We have a team of Science and Business graduates complimented by a management team with years of experience. We work closely with our customers to achieve their specific goals in the design and manufacture of custom optics and mechanics to their exact requirements.

Stock Optic Solutions

We also hold a large inventory of stock optical components for use in ultra-violet, visible, near infrared and far-infrared applications that can be customized at short notice to meet your specific requirements.

Optical Expertise in the Oil and Gas Industry

We have a considerable customer base across the sector and as a long-term partner with many spearheads within the field, our optical components are regularly specified for large- and small-scale applications such as:

Optics for Continuous Emission Monitoring

A continuous emission monitoring system (CEMS) is the necessary equipment needed to determine a gas or particulate matter concentration or emission rate by means of pollutant analyser measurements. Monitoring by CEMS is highly regulated and evaluation of performance specifications are required.

Knight Optical can supply singlet lenses and optical quality windows made from a variety of infrared (IR) materials to accommodate monitoring using a broad range of the IR spectrum. Materials commonly used are, calcium fluoride (CaF2), Germanium (Ge), Silicon (Si), fused silica or Quartz (SiO2), Magnesium Fluoride (MgF2) and Sapphire (Al2O3).

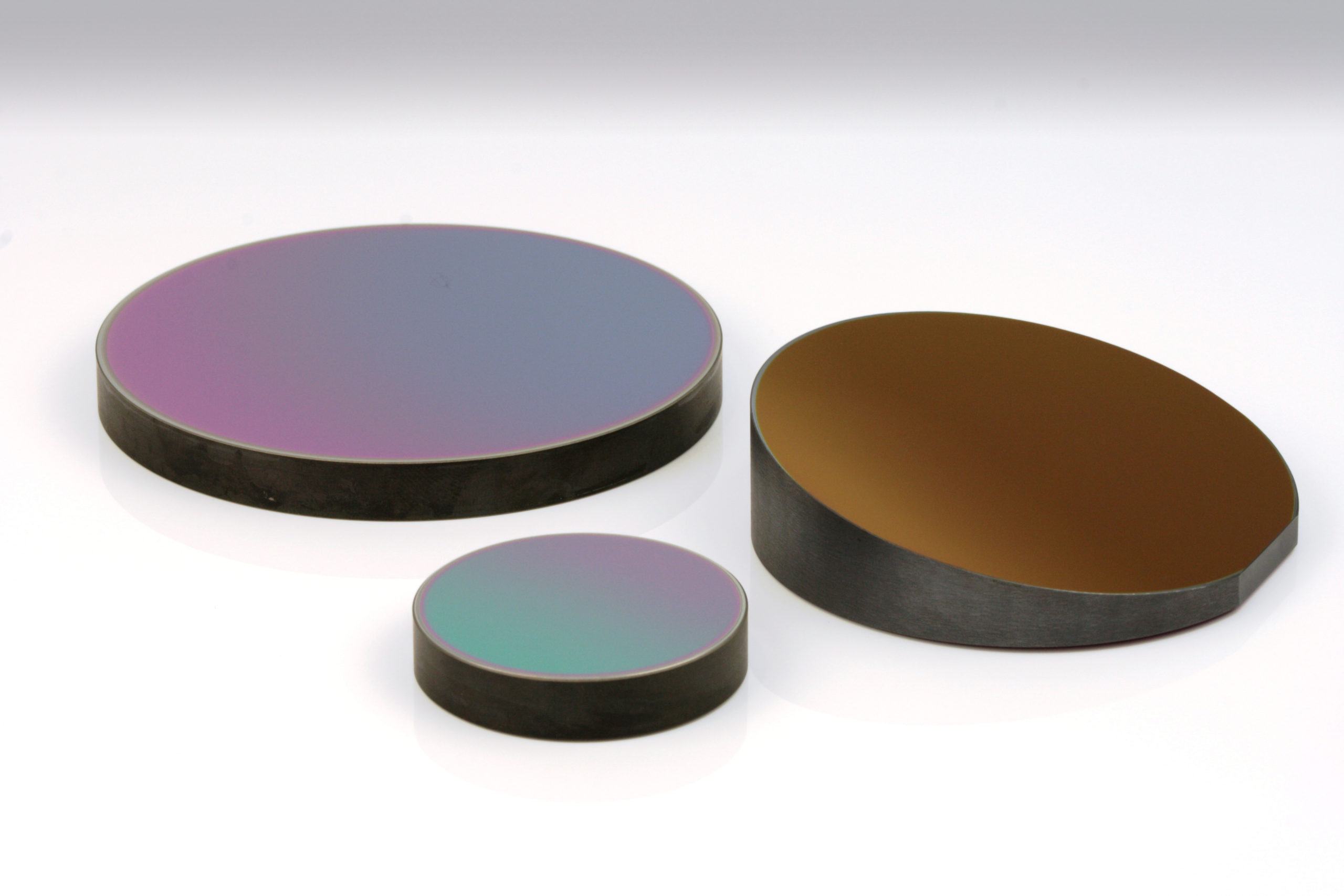

Infrared gas band filters

Our custom designed gas band filters are created using silicon, sapphire or germanium, all of which are highly robust and suitable for use in harsh environments. The filters are specifically used to detect the presence of gas. For detection of specific spectral peaks, interference bandpass filters can be used, for example:

| Carbon Monoxide (CO) | 4.73µm |

| Nitric Oxide (NO) | 5.24µm |

| Nitrogen Dioxide (NO2) | 6.17µm |

| Sulphur Dioxide (SO2) | 7.42µm |

| Hydrogen Chloride (HCl) | 3.55µm |

| Carbon Dioxide (CO2) | 10.7µm |

Lenses for Infrared Applications

Crafted from robust materials including calcium fluoride, germanium, silicon, fused silica, magnesium fluoride, zinc selenide and sapphire, our precision grade lenses are fully customisable in terms of size, shape and materials. Our experts will provide the guidance needed to optimise the design of the lenses and meet any specification.

Windows

Optical windows enhance transmission and reduce absorption and reflection. They play a vital role in protecting optical systems from the outside environment. Selection rests on the transmission properties, coefficient of thermal expansion, refractive index, density and durability of the material, amongst other considerations. Windows can be made of a variety of materials to suit your required application. Ensuring your choice in optical windows is right for your application is something our experts will guide you on.

Gas cells

Gas transmission cells are used to contain gases at pressures up to 4 bar using stainless steel enclosures and magnesium fluoride windows. We offer a broad variety specifically suited to gas analysis applications, ranging from short path length cells for percent level concentration measurement to long path length cells for part-per-billion concentrations. Bespoke options include fixed and variable path length gas cells, and ambient temperature and heated gas cells.

Mirrors

Front surface mirrors are used for beam steering and reflecting. Your specific application will require particular materials to cope with harsh environments, coatings including: enhanced aluminium, protected gold for infrared wavelengths and highly reflective (>99%) dielectric mirror coatings can be applied to further enhance performance.

Understanding Quality

Our rigorous testing procedures – using advanced metrology equipment and skilled QA inspectors – ensure all our products satisfy even the most specific requirements. This applies to one-off custom parts and large production runs. Every single component we supply is proven to perform. We will also provide you with all the information you require for your documentation. We can reassure you that there is transparency on your ordered items including a metrology report and a certificate of conformance to quality standards. We are able to provide you with as much information as required to ensure that legal obligations are met, allowing your instrument to be approved for use as soon as possible.

Our rigorous testing procedures – using advanced metrology equipment and skilled QA inspectors – ensure all our products satisfy even the most specific requirements. This applies to one-off custom parts and large production runs. Every single component we supply is proven to perform. We will also provide you with all the information you require for your documentation. We can reassure you that there is transparency on your ordered items including a metrology report and a certificate of conformance to quality standards. We are able to provide you with as much information as required to ensure that legal obligations are met, allowing your instrument to be approved for use as soon as possible.

Knight Optical value every one of our customers, and therefore you will be assigned a dedicated account manager, who cares as much about your project as you do. They make the process of getting a quotation to receiving an order, as smooth as possible. We go above and beyond ensuring that your supply chain experience is as stress-free as possible.

Commonly Ordered Optics

Our 2022/2023 Catalogue

Inside Knight Optical’s catalogue you’ll find details of the industries we serve as well as the many other services we can offer. It also showcases hundreds of our most popular products, supported by useful technical information, to help you choose the right part for your application.

Click below to view our digital catalogue now.